PRODUCTION TECHNOLOGY

Exclusive technology: Part manufacturing in high pressure full carbon prepreg.

All masts / front wings / stabilizers profiles of our windfoils are made of carbon.

For our fuselages, we offer 2 different technologies: full prepreg carbon or Aluminum Aero: alloy specific to aeronautics, this material is solid, lightweight and ultra-rigid.

This technological development allows us to maintain the level of performance of our foils whilst reducing production costs to offer more attractive retail prices.

Our Alu Aero fuselages are machined directly in our workshop in France.

Whatever the technology used, they are built by SELECT / SM COMPOSITE.

The advantages of the SELECT technologies :

- The moulding and machining ensure a high precision manufacturing and a constant production.

- Thanks to the use of pre-preg, we can put reinforcements in differents directions to get the twist and flex values we are looking for.

- We master of production process end to end : our hybrid carbon / aluminium foils benefit from the same hard work and dedication as the SELECT fins…no compromise on quality !

HIGH PRECISION MACHINE

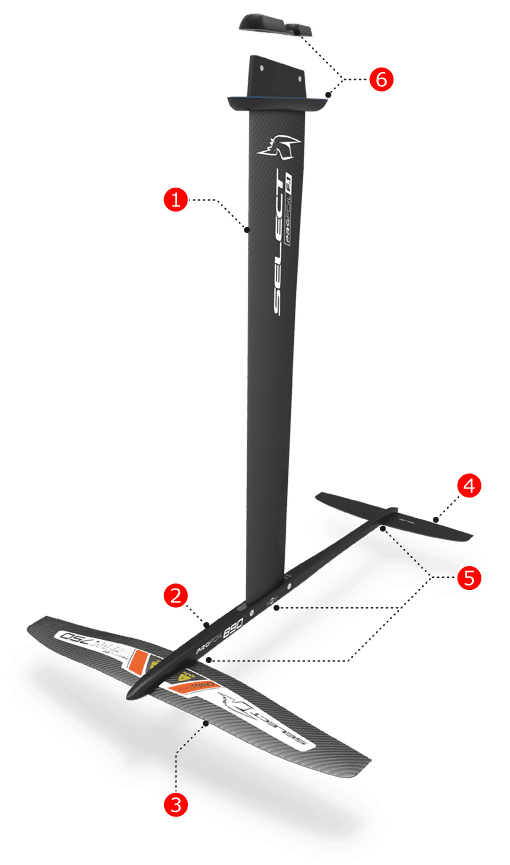

CONSTRUCTION DETAILS OF THE ProFOIL.F1

Construction : monolithic full carbon prepreg

– UD carbon fiber hi-modulus 390 GPA HM

– Biaxial carbon 430 GPA HM

Length : 90 cm

Fuselage fixture : stainless steel screws and bolts / Additional security lateral fixture

Finishing : Sanding 1200 grit

– Alu.Aéro 890mm

– Alu.Aéro 1060mm

Construction : full carbon prepreg.

Powerful profile with strong acceleration reserve

Finishing : sanding / grain 1200 > water on water contact

Fixing : 3 stainless steel screws / Diameter 6 mm

Construction : Carbon fr4 > High precision machining

Stabilizer built into the fuselage : very low drag

Finishing : sanding / grain 1200

Fixing : 2 stainless steel screws / Diameter 6 mm.

High quality Stainless steel screws / M6

CP TOP to distribute the clamping forces on the deck.

CP BOTTOM to lock and secure the forces on the hull